Hefei Hagong Kuxun Intelligent Technology Co., Ltd. was established in 2014 and is a national high-tech enterprise specializing in the field of intelligent mobile robots and automation systems. The company's business covers intelligent industrial unmanned mobile robots, intelligent warehousing and logistics integration systems, intelligent inspection robots, etc., providing intelligent logistics solutions for all scenarios and 24/7. As a national level specialized and innovative "little giant" enterprise and Anhui Provincial Engineering Research Center, the company is in a leading position in multiple fields such as intelligent industrial mobile robots, intelligent three-dimensional warehousing, and intelligent inspection.

Below is an introduction to the one-stop solution for intelligent warehousing, one of the important sectors of the company.

·A one-stop solution for intelligent warehousing---The IoT warehouse management solution, combining 5G+intelligent equipment+3D digital twin technology, is committed to reducing costs and increasing efficiency for enterprises, and helping to upgrade the systematization and intelligence of enterprise logistics management.

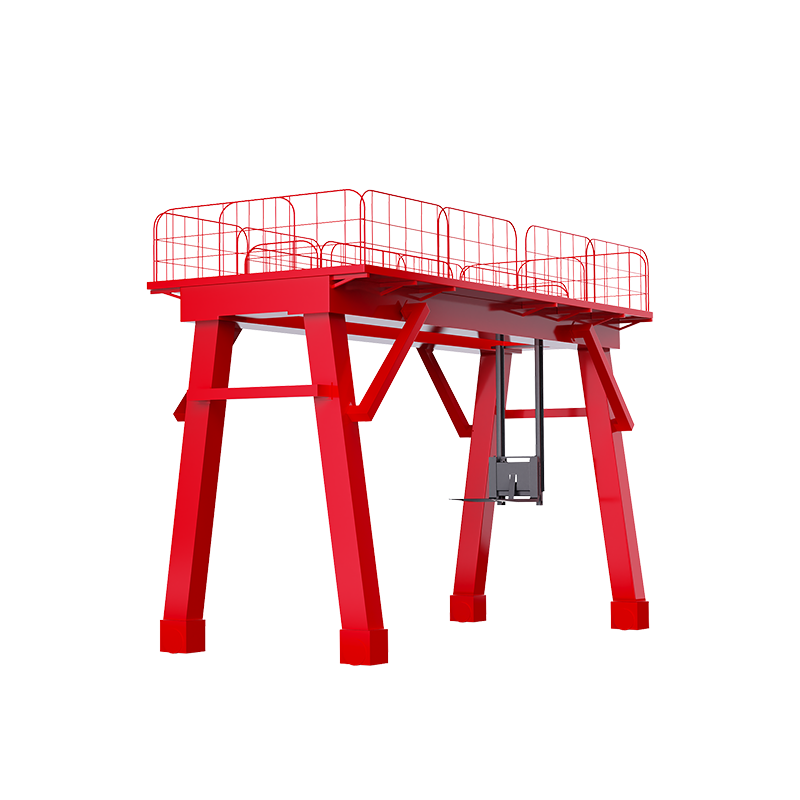

·Stacker crane three-dimensional warehouse---Make full use of space, store goods on multiple shelves, and achieve efficient storage and retrieval of goods through automated mechanical equipment - stackers.

·Four way dense car depot---Modern intelligent warehousing solutions are particularly suitable for efficient and intensive cargo storage and picking environments. This system combines advanced logistics technology and automation equipment, significantly improving the space utilization and operational efficiency of the warehouse.

·RGV shuttle car---Through PLC programming control, tasks such as picking up, transporting, and placing goods can be achieved, and communication can be carried out with the upper computer WCS or WMS system. Combined with identification technologies such as RFID and barcode, automated identification and access functions can be achieved.

·Digital twin platform---Integrate Internet of Things (IoT), big data, artificial intelligence (AI), cloud computing, and simulation technologies to establish highly accurate virtual models of physical entities, processes, or systems.

A one-stop solution for intelligent warehousing

The one-stop solution for intelligent warehousing is an IoT warehousing management solution that combines 5G+intelligent equipment+3D digital twin technology; The system effectively improves space utilization, reduces human scheduling, realizes warehouse information management, improves warehouse operational efficiency, and reduces labor costs; At the same time, it can also achieve real-time monitoring and analysis of warehousing data, help enterprises adjust warehousing strategies in a timely manner, improve the accuracy of warehousing management, effectively improve warehousing and transportation efficiency, and enhance management level; Realize real-time intuitive perception of warehouse logistics operation processes, data statistics, indicator analysis feedback, information tracking and tracing, etc; Dedicated to reducing costs and increasing efficiency for enterprises, and assisting in the systematic and intelligent upgrading of logistics management.

Stacker crane three-dimensional warehouse

Working principle:The stacker crane moves horizontally in the tunnel driven by a walking motor, and the lifting motor controls the lifting of the cargo platform. The fork mechanism is responsible for picking up and placing goods. The stacker crane is equipped with a precise position detection system, such as a walking address recognition system, a lifting address recognition system, and a fork position sensor, to ensure that it can accurately reach the designated cargo location.

Application advantages:

1. Efficiently utilize space and increase storage capacity per unit area.

2. Realize the automation of goods storage and retrieval, reduce manual labor intensity and error rate.

3. Real time monitoring of inventory status, seamless integration with enterprise ERP, MES and other information systems, to improve the overall response speed of the supply chain.

In short, the stacker crane three-dimensional warehouse, with its high degree of automation and informatization, is widely used in manufacturing, logistics, e-commerce and other industries, becoming one of the important symbols of modern intelligent warehousing.

Four way dense car depot

The four-way shuttle dense warehouse is an important technological innovation in the field of modern warehousing and logistics, providing enterprises with more flexible, efficient, and intelligent warehousing solutions.

Advantages:

High storage density:The four-way shuttle can flexibly adjust the storage space without the need to reserve a large number of channels, greatly improving the space utilization of the warehouse and significantly improving the storage density compared to traditional warehouses.

Flexibility:Capable of handling various SKU quantities and frequently changing storage needs, responding quickly to order demands, and adjusting storage strategies.

High degree of automation:Reducing manual intervention allows for 24-hour uninterrupted work, which helps to reduce labor costs, improve work efficiency and accuracy.

Safety and stability:Equipped with comprehensive safety protection measures and fault self diagnosis capabilities, ensuring stable system operation.

The four-way shuttle dense warehouse is an important technological innovation in the field of modern warehousing and logistics, providing enterprises with more flexible, efficient, and intelligent warehousing solutions.

RGV shuttle car

RGV is the abbreviation for Rail Guided Vehicle, also known as Rail Shuttle.

The rail shuttle car mainly consists of a track, a vehicle body, walking wheels, a walking motor, a walking wheel guide mechanism, a conveyor, a conveying motor, a sliding contact power supply system, a polyurethane buffer, and an electrical control cabinet control system. A shuttle car that operates on a fixed track, usually on a straight or circular track, to transport goods to a designated location or designated connecting equipment.

Advantages and characteristics:

Strong adaptability, variable frequency speed regulation, high flexibility, strong scalability, and high efficiency.

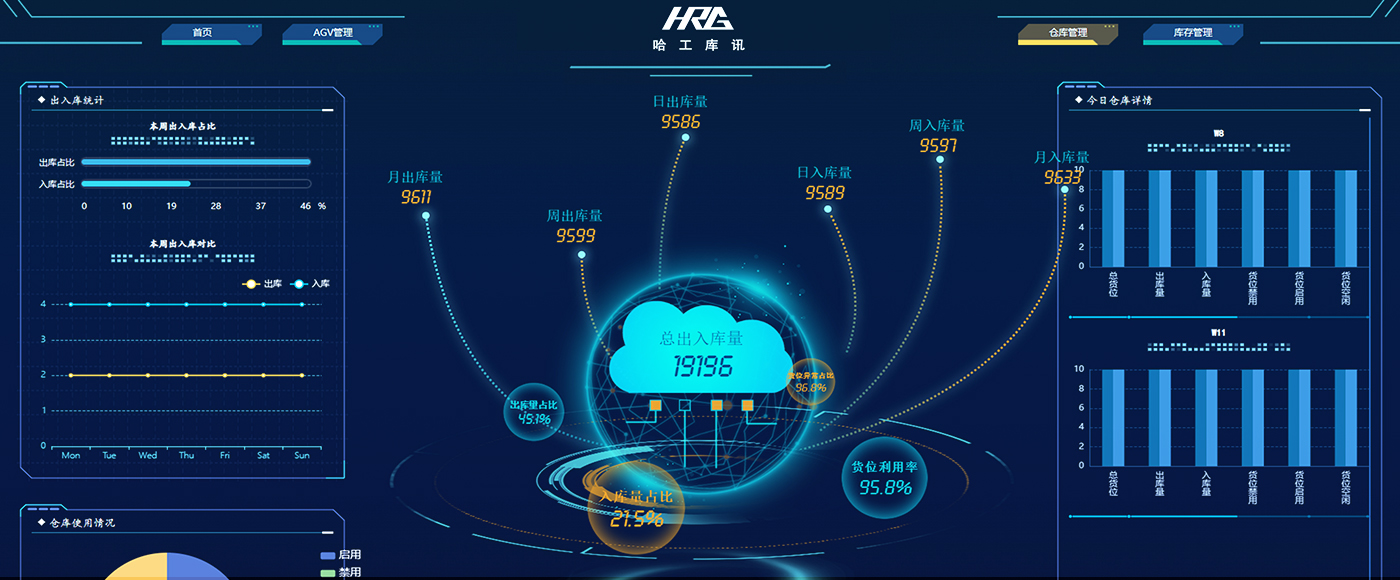

Digital twin platform

Digital modeling:Based on detailed design data, material properties, working principles, and other information of physical systems, construct a high fidelity virtual model, including geometric structure, dynamic characteristics, thermodynamic behavior, and other details.

Real time monitoring and data analysis:By continuously collecting operational data of physical systems through IoT devices, real-time status monitoring is achieved to analyze performance indicators, predict potential faults, and optimize operation and maintenance strategies.

Simulation and prediction:Utilize simulation tools and techniques to simulate the performance of physical systems under different conditions, anticipate future conditions, evaluate decision-making effectiveness, and test improvement plans.

Full lifecycle management:Covering the entire process of designing, producing, deploying, using, maintaining, and retiring physical entities, digital twins are continuously updated and reflect the changes in the entity's state throughout its entire lifecycle.

Collaborative optimization and decision support:By integrating across disciplines and fields, we help enterprises make more accurate decisions in product design, manufacturing, operation, and other stages, improve efficiency, reduce costs, and enhance sustainability.

Digital twin technology is widely used in various fields such as intelligent manufacturing, helping enterprises, institutions, and individuals better understand and manage complex physical systems.

Back

Back