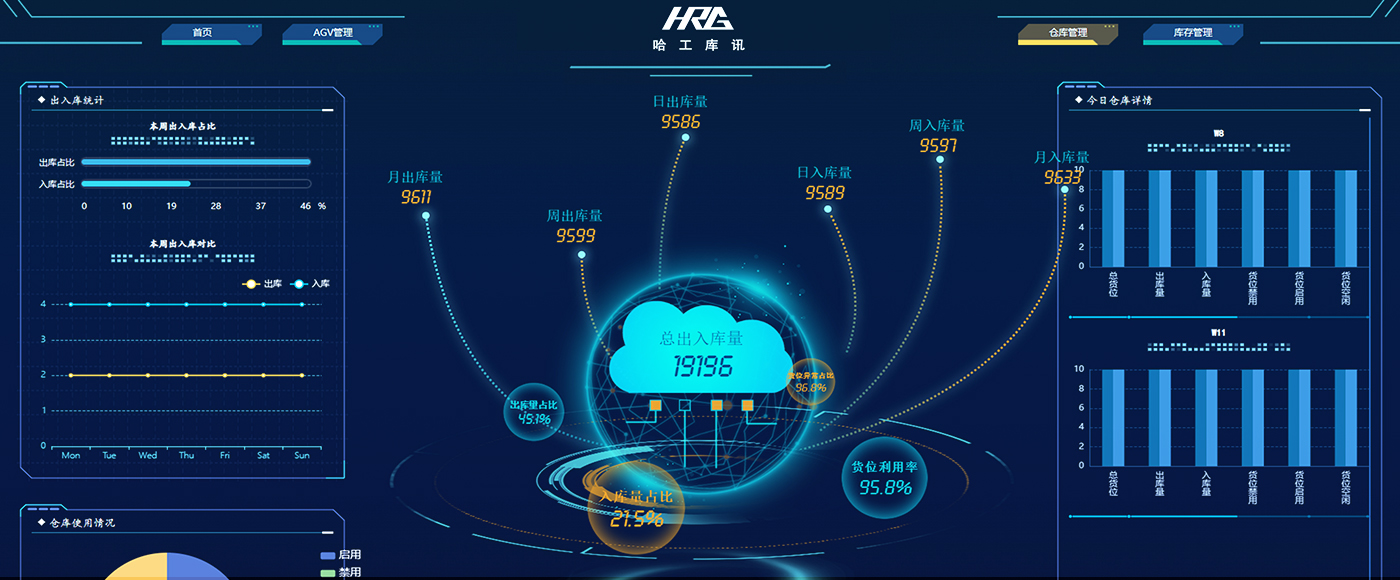

Ha Gong Ku News: 5G Outdoor Unmanned Forklift Recognized by Tongwei Group, Newly Upgraded and Received Order Again

Entering the peak season of production and operation, Harbin Kuxun's workshop is bustling with activity. Recently, Kuxun has once again reached a cooperation agreement with Tongwei Group to upgrade its flagship products and win the bid for the second phase project of 8 sets of "outdoor unmanned forklifts" by Tongwei Solar Energy (Jintang) Co., Ltd.

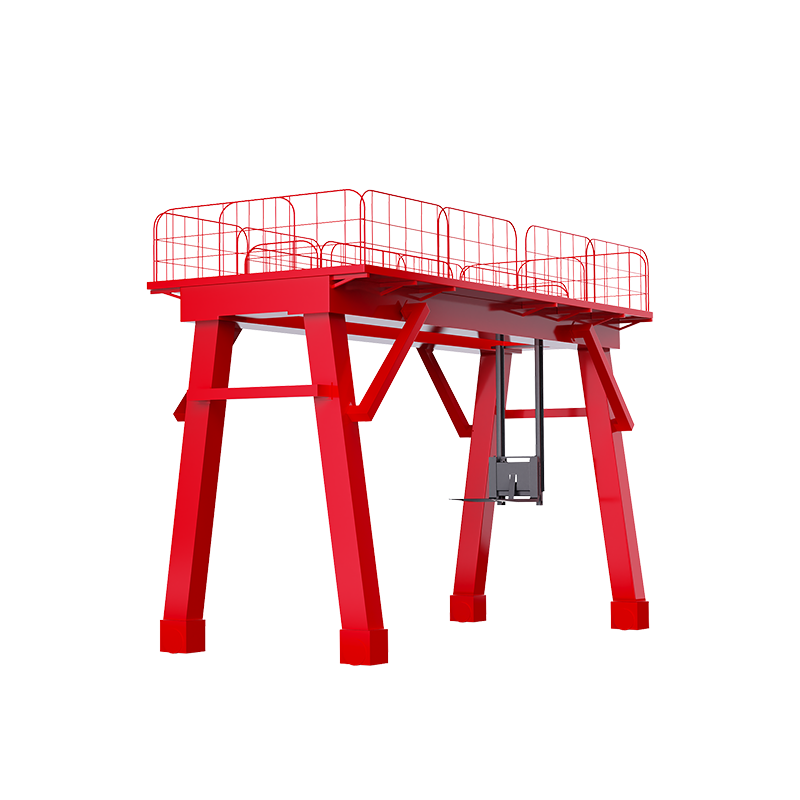

Engineer debugging 5G outdoor unmanned forklift

01

Meikai Second Outdoor Unmanned Forklift Enters 5G Smart Park Again

It is reported that the Tongwei Solar Jintang Base is the first 5G smart park in the photovoltaic industry created by Tongwei Group globally. The overall plan for the project is phase four, mainly focusing on efficient battery unmanned intelligent manufacturing routes, constructing intelligent chemical plants, digital workshops, logistics warehousing and related supporting facilities. Thanks to the application of 5G technology, robotic arms, outdoor unmanned forklifts, and information systems, this base has become a benchmark for intelligent manufacturing in the photovoltaic industry by Tongwei Group and has been included in the group's 40th anniversary achievement model.

Efficient operation in 5G smart parks

In the first phase of the project, multiple 5G outdoor unmanned forklifts launched by Hagong Kuxun were successfully integrated with the entire smart park in terms of speed, frequency, channel, signal strength, coverage density, etc. using advanced 5G technology; Connecting with the track;, Successfully landed in the Jintang base factory area and received strong application, providing intelligent distribution services for raw materials, finished products, chemical auxiliary materials, solid waste, and other intelligent manufacturing production lines for the first phase of the project. Solved the problem of warehouse and production line distribution and connection throughout the factory, and reduced the number of forklift crew members from the previous 10 to the current 3.

Due to its outstanding performance in the first phase of the project, the 5G outdoor unmanned forklift was awarded a second phase order at the base, further deepening the cooperation between the two parties.

02

Renovation, upgrading, and upgrading to meet the adaptability of complex outdoor environments

Based on the experience of technology layout and production operation exploration in customer application sites, Hagong Kuxun has completed comprehensive functional upgrades of its products in navigation strategy, network support, rainwater protection, safety protection, and other aspects, further enhancing the adaptability of 5G outdoor unmanned forklifts to more complex outdoor environments. It is committed to creating "5G+unmanned forklift" in the industrial field.

New functional upgrades enhance adaptability to more complex outdoor environments

The newly upgraded 5G outdoor forklift has strengthened its path planning ability in large scenes, better meeting the outdoor operation needs of millions of square meters at Tongwei Base, and further solving the application difficulties in extremely complex environments such as outdoor and cold storage. At the same time, devices such as fork inspection sensors, oblique downward laser scanning, rear laser obstacle avoidance, left and right laser obstacle avoidance have been installed, forming a 360 ° no dead angle "defense". In addition, with the support of visual algorithms, non 2D planar obstacles such as suspended and mobile can be better identified, and tray adaptation, autonomous obstacle avoidance, and autonomous path planning can be achieved, greatly reducing the waiting time for equipment to stop.

In terms of waterproofing level, the new product has achieved IP65, which meets the requirements for vehicles with visibility within 100 meters to operate normally in foggy weather, greatly reducing the impact of weather on equipment in outdoor application environments. In terms of operation scheduling, the "free riding" dispatching system improves the efficiency of receiving orders for each device through global optimization, centralized dispatching, and chain dispatching, minimizing the total freight distance and time, avoiding empty runs, and achieving efficiency improvement and energy consumption reduction. In addition, adaptive adjustment of the fork has been added to ensure a positioning accuracy of ± 5mm, greatly improving the efficiency of logistics handling.

03

Continuously improving and empowering intelligent logistics in industrial scenarios

At present, the logistics and freight industry in China is in a period of vigorous development. Faced with low manual efficiency, harsh working environment, frequent safety and quality accidents, the demand for outdoor unmanned forklifts in industrial scenarios is on the rise. Based on its strong research and development capabilities and fully leveraging the resources of the research institute, Hagongkuxun has achieved multiple technological achievements in the independent research and development of intelligent mobile operation robots. Currently, it has launched 20 products, applied for 53 patents, and completed more than 60 landing projects.

In addition, the company has also received support from the Anhui Provincial Development and Reform Commission's artificial intelligence project, and has partnered with HRG Hefei Research Institute to establish the Anhui Provincial Intelligent Mobile Robot Engineering Research Center, continuously strengthening its strength in product technology, marketization, industrialization, and other aspects.

HaGongKuXun Intelligent Mobile Operation Robot Series Product Services for Different Scenarios

Zhang Weiwei, General Manager of Harbin Institute of Technology, stated that the upgraded 5G outdoor unmanned forklift will better leverage its technological value, deeply explore market demand, provide high-quality solutions for mobile robots in industrial application scenarios, and promote the improvement and efficiency of the intelligent manufacturing industry.

Back

Back