Project Overview

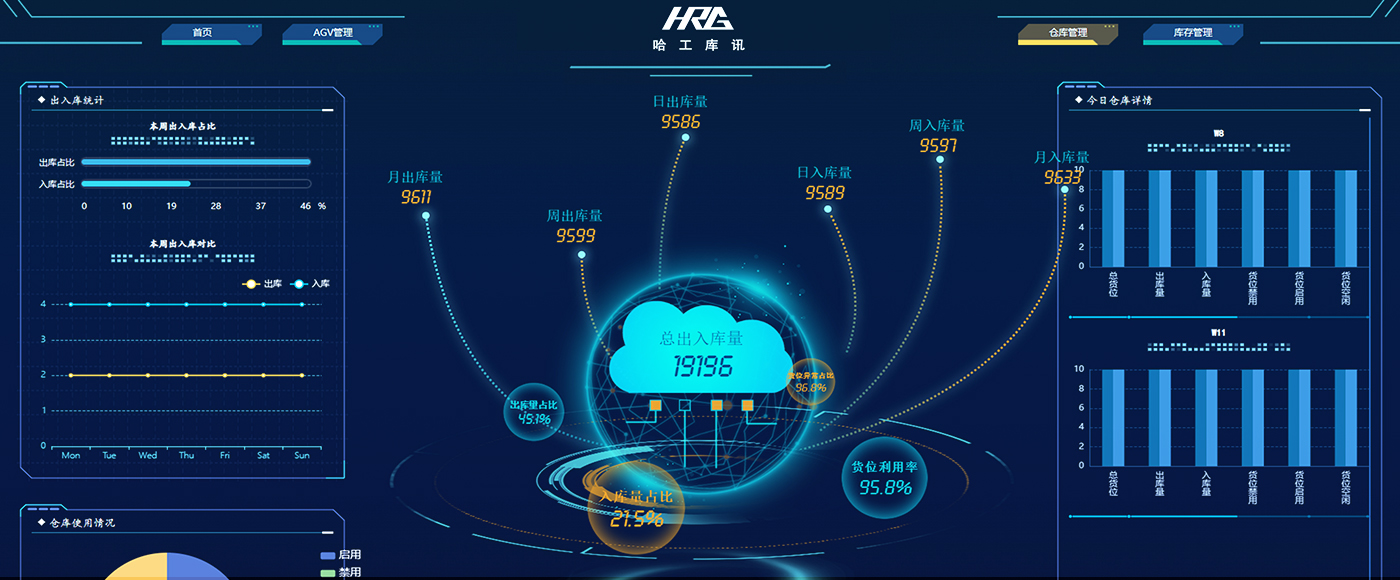

The landing application of the AGV intelligent logistics system project of a green intelligent factory in a household appliance industry has opened up the "last mile" of products from the production line to the warehouse. Through the centralized scheduling of AGV by the system, the whole machine warehousing and networked and information-based collaborative management of the warehouse have been realized; In addition, the system realizes the full process of unmanned distribution of raw materials, online preparation, and offline storage of finished products. It can be used for distribution and transportation of different types of materials such as light guide plates, membranes, machines, speakers, small hardware, and light strips, as well as automatic dock connection for loading and unloading, helping enterprises upgrade their intelligence.

Solution

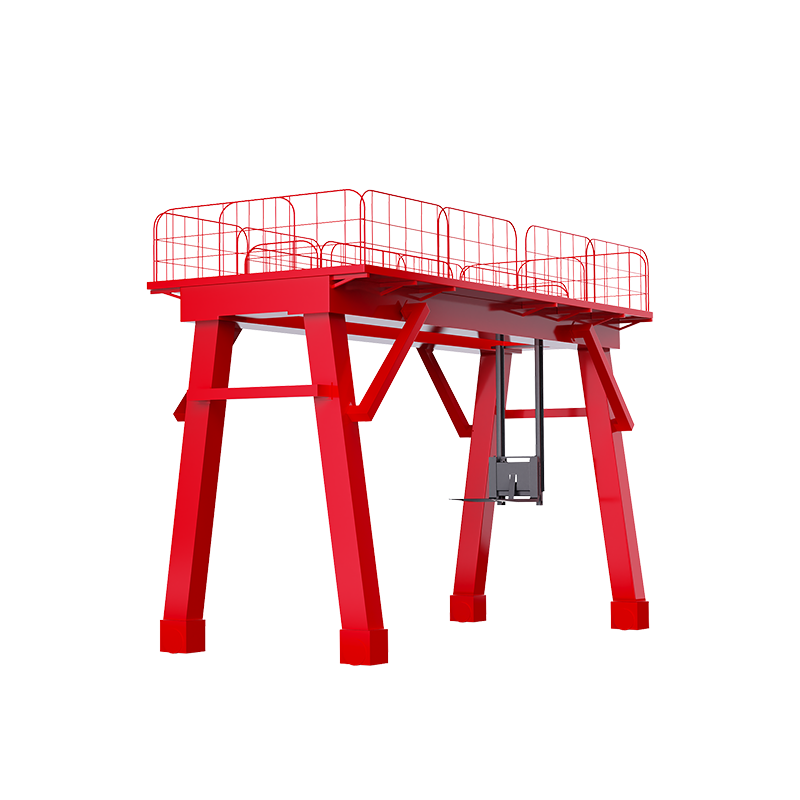

Adopting a dual steering wheel with a drum mounted AGV, it can achieve forward, backward, left and right travel, automatically dock with the production line rollers and intelligent loading and unloading machines, and provide accurate positioning information for position and angle while operating at high speed. The robot is equipped with a safety LiDAR in front and behind, with a 360 ° scanning range of objects within 3 meters. It can flexibly set the safety obstacle avoidance range and intelligently switch the obstacle avoidance mechanism, suitable for safety applications in complex environments.

Back

Back