Project background

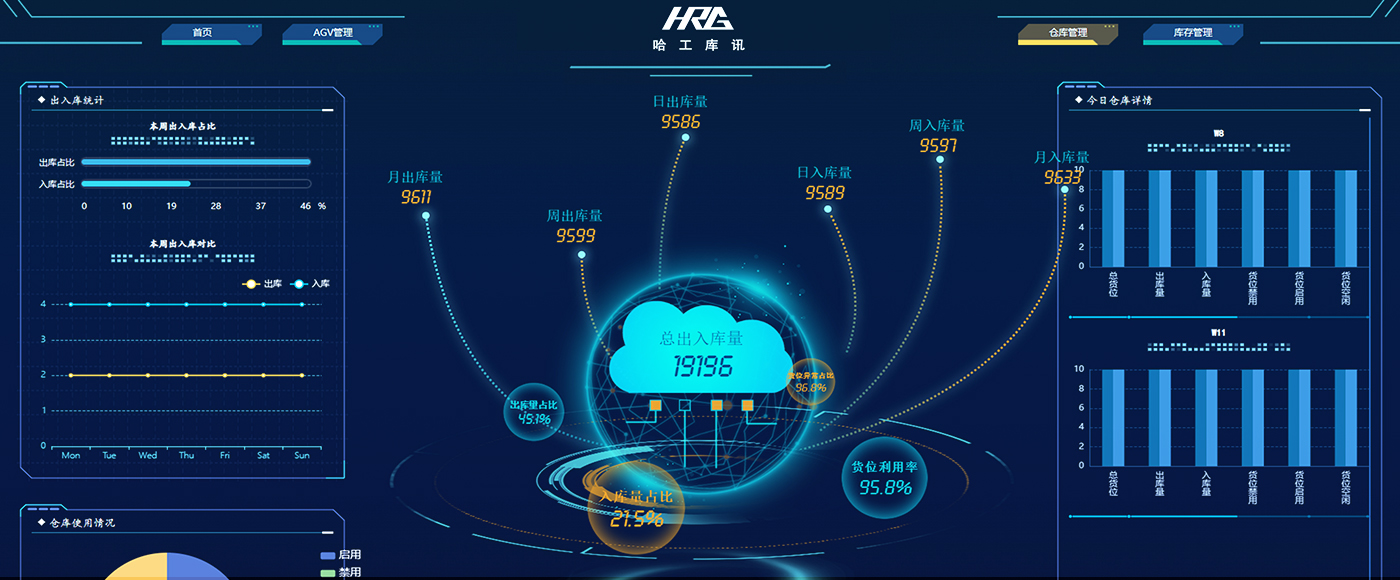

This project meets the requirements of "high informatization and moderate automation" in the logistics construction of the State Grid industry. Through project research and planning design, it can achieve the goals of improving operational efficiency, reducing labor intensity, reducing logistics costs, and meeting the national energy-saving and emission reduction requirements.

Project Introduction

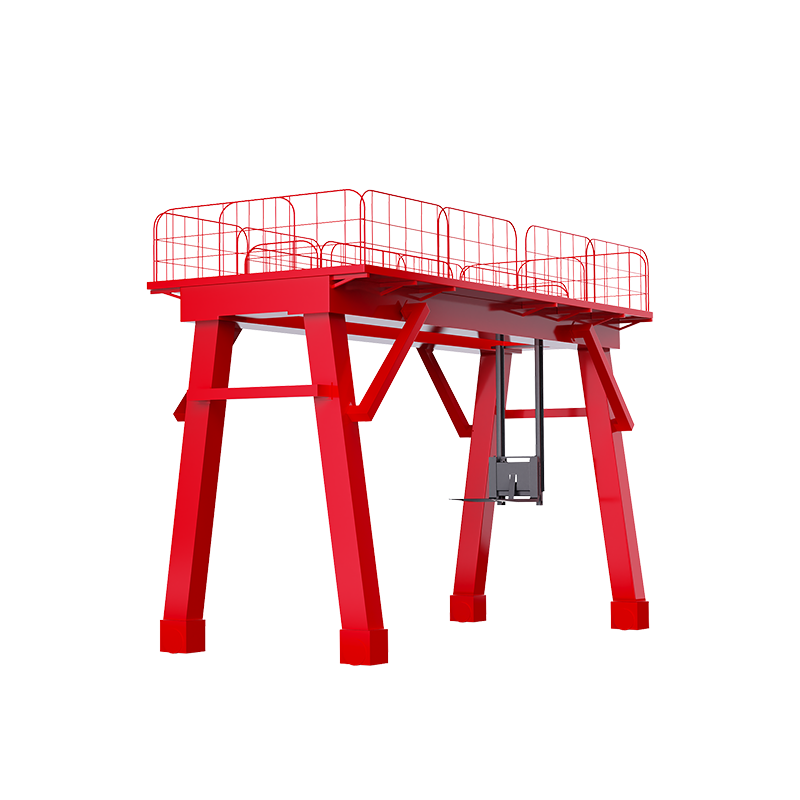

The planned shelf space for this project is 336, with a rated capacity of 1.5T/P, and tray specifications of 1300mm * 1100mm * 1585mm. The overall plan adopts a combination of multiple forms such as automated high-level shelf storage, pallet ground storage, pallet crossbeam shelf storage, and automatic AGV storage for box cargo using a double column and double depth stacker crane to complete the storage operation of goods. Divide the warehouse into functional areas such as storage and inspection area, storage area, heavy-duty forklift storage area, hidden flat storage area, intelligent unmanned emergency warehouse area, dismantling and stacking area, and high-level intelligent three-dimensional warehouse in an organic manner.

In the intelligent storage system, in order to meet the storage needs of different forms of materials, a dismantling and stacking area is set up. This area is equipped with pallet conveying, box conveying, dismantling and stacking robots, and empty pallet stacking machines to achieve material detection and dismantling and stacking operations.

Back

Back